DMG MORI DECKEL MAHO DMU80P hi-dyn

DMG MORI DECKEL MAHO DMU80P hi-dyn

or

Call 262-432-7474

Description

5-AXIS MACHINING CENTERS

DECKEL MAHO DMU80P hi-dyn

SUBJECT TO AVAILABILITY, AND TERMS AND CONDITIONS FOLLOWING, WE OFFER FOR YOUR CONSIDERATION:

One used 2002 DMG MORI DECKEL MAHO DMU80P hi-dyn 5-AXIS Universal Machining Center:

Machine is IN STOCK, fly into Milwaukee, WI (MKE) to inspect

>>**This machine is bank owned, they are OPEN FOR OFFERS**<<

This machine was made at DMG MORI-Pfronten in Pfronten, Germany

-DESIGN CONCEPT-

This machine is TWO machines in one because of the universal milling head

that swivels from horizontal to vertical position and vice versa. This

allows complete machining in one set-up for up to 5-sides and 5-axes

machining.

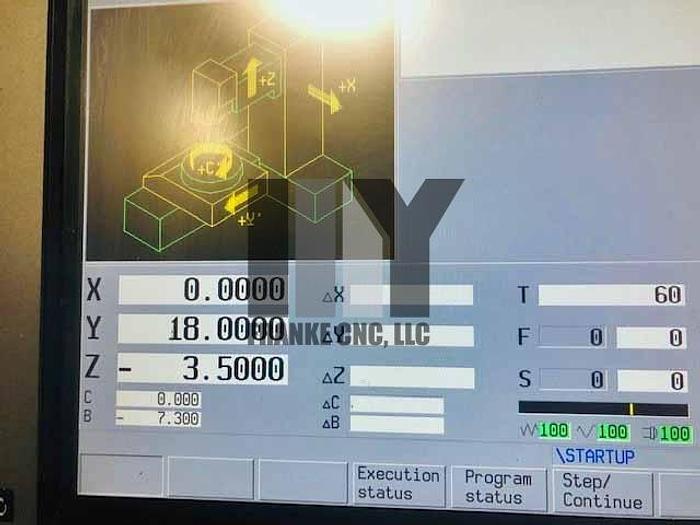

-CONTROL-

HEIDENHAIN MillPlus IT with Ethernet & Electronic Handwheel

-WORKING RANGE-

-MAXIMUM WORKPIECE DIMENSIONS-

-4th AXIS NC ROTARY TABLE-

Clamping surface 35.4" dia x 24.8" (900mm diameter x 630mm front to back)

-5th AXIS UNIVERSAL MILLING HEAD WITH CONTROLLED B-AXIS-

This machine is equipped with a universal milling head that swivels from

horizontal to vertical position and vice versa. In addition the milling

head has a controlled B-Axis. Swivel angle from vertical position 0 deg

to the left -7.3 degrees(in direction of tool magazine)and to the right to

horizontal position +180.3 degrees for a total 187.6 degrees swivel range.

This allows complete machining in one set-up for up to 5-sides and 5-axes

machining.

-MAIN SPINDLE DRIVE-

Spindle speed range 20-18,000 rpm motor spindle

-FEED DRIVES-

-60 POSITION TOOL CHANGER-

Maximum tool diameter with no empty neighboring pockets 3.94" (100 mm)

-EXTERNAL FLOOD COOLANT-

-COOLANT THRU THE SPINDLE-

-INSTALLATION-

Total weight of machine at base incl. workpiece weight 21,605 lb(9,800 kg)

-HEIDENHAIN GLASS SCALES X/Y/Z AXES DIRECT PATH MEASURING SYSTEM-

-HEIDENHAIN ROTARY ENCODERS B/C AXES DIRECT PATH MEASURING SYSTEM-

-EQUIPPED WITH-

Fully enclosed protection cabin

BLUM Laser tool measuring in machining area:

Automatic withdrawal of the measuring unit in a protected housing

Tool length & tool diameter measuring in both horizontal/vertical

Preparation for Renishaw MP 10 infrared measuring probe

Spray pistol with pump 14.5 psi/10.4 gpm (1 bar/40 l/min)

Production package consisting of:

-Coolant tank 160 gallon (600 l) with automatic gap sieve cleaning

-580 PSI (40 bar) coolant thru the spindle form AD

-Chip conveyor

-Rotating clear-view window on side window

Specifications

| Manufacturer | DMG MORI |

| Model | DECKEL MAHO DMU80P hi-dyn |

| Year | 2002 |

| Condition | Used |

| Stock Number | 064329 |

| Status | Available |

| Number of axis | 5-Axis |

| Tool changer | 60 ATC |

| Control | HH MillPlus IT |

| Spindle | 18,000 rpm |

| Spindle taper | CAT 40 |

| X axis | 31.5" (800 mm) |

| Y axis | 27.6" (700 mm) |

| B axis | -7.3 to +187.6 degrees |

| Z axis | 23.6" (600 mm) |

| C axis | 360 x 0.001 degrees |

| Build date | 08/2001 in Germany |

| First installed new in the usa | 02/2002 |

| X-axis (longitudinal) | 31.5" (800 mm) |

| Y-axis (transverse) | 27.6" (700 mm) |

| Z-axis (vertical) | 23.6" (600 mm) |

| Maximum workpiece diameter | 36.2" (920 mm) |

| Maximum workpiece height | 39.4" (1,000 mm) |

| Maximum workpiece weight | 1,760 lbs (800 kg) |

| Maximum table load | 1,760 lbs (800 kg) |

| Rotation range | 360 x 0.001 degrees (Full 4th Axis) |

| T-slots | 9, 14 H7/63 mm/0.55 H7/2.4 |

| Type | Brushless AC/Digital |

| Power 40% duty cycle (s3) | 37.5 hp (28 kW) |

| Power 100% duty cycle (s1) | 25.5 hp (19 kW) |

| Number of gear steps | None |

| Maximum spindle torque | 89 ft/lb (121 Nm) |

| Spindle bearing diameter front | 3.15" (80 mm) |

| Automatic swivel horiz/vert | Approximately 4 seconds |

| Retention knob | ISO/DIS 7388/II type B |

| Feed rate | 0.04"-590 IPM (1-15,000 mm/min) |

| Rapid feed (x/y/z) | 1,575 IPM (40 m/min) |

| Acceleration | 5 m/s-2 |

| Feed power (x/y/z) | 10 kN |

| Ballscrew (x/y/z) | 40x20/40x20/40x20 mm |

| Magazine type | Horizontal chain, double gripper |

| Number of pockets | 60 |

| Maximum tool weight | 22 lb (10 kg) |

| Maximum tool diameter with empty neighboring pockets | 6.3" (160 mm) |

| Maximum tool length | 13.8" (350 mm) |

| Tool change time | Approximately 5.5 seconds |

| External coolant jets pressure | 21.7 PSI (1.5 bar) |

| External coolant jets flow rate | 10.6 gpm (40 l/min) |

| Chip conveyor pump output pressure | 21.7 PSI (1.5 bar) |

| Chip conveyor pump output flow rate | 15.8 gpm (60 l/min) |

| Coolant tank capacity | 160 gallon (600 l) |

| Pump output | 6 gpm (23 l/min) |

| Pump pressure | 580 PSI (40 bar) |

| Compressed air | 87 PSI (6 bar) |

| Input resolution | 0.001 mm |