ROEDERS RXP 400

ROEDERS RXP 400

or

Call 262-432-7474

Description

VERTICAL MACHINING CENTERS

RXP 400

SUBJECT TO AVAILABILITY, AND TERMS AND CONDITIONS

FOLLOWING, WE OFFER FOR YOUR CONSIDERATION:

One used 2012 ROEDERS RXP 400 High Speed 3-Axis Vertical Machining Center:

SERIAL NUMBER ---- At Inspection

Machine built in Soltau, Germany in 2012; first installed new in US 3/2013

-BASE MACHINE, INCLUDING THE FOLLOWING-

High speed milling machine with high stiffness for highest precision and

surface quality in three linear axes. The NC control has been developed

especially for high dynamics in 3D milling operations.

Patented friction-freee weight counterbalance in teh Z-axis for optimal

precision.

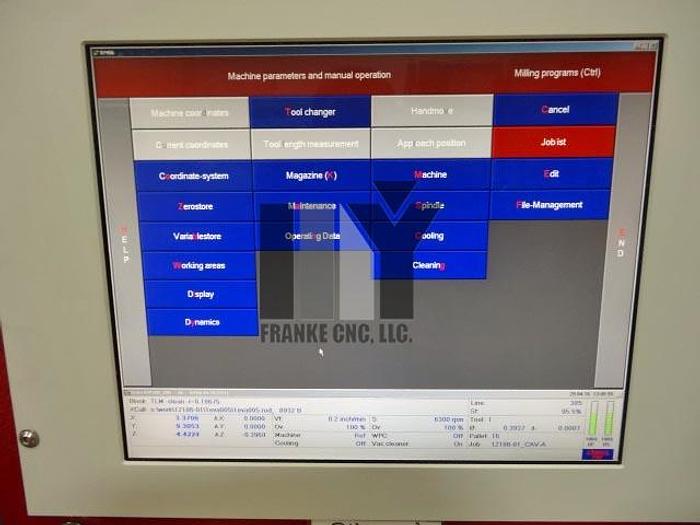

Intel Pentium based Roeders High Speed CNC control RMS6

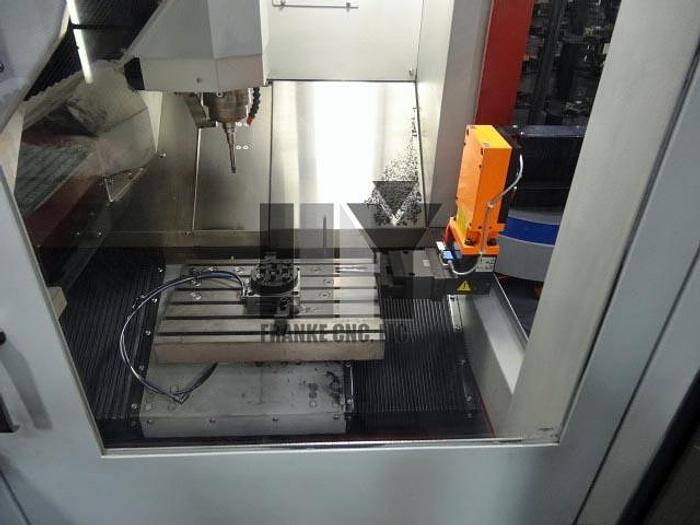

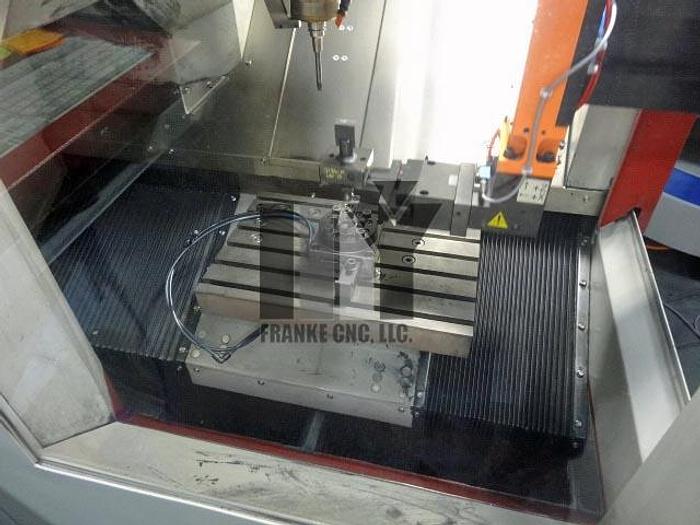

Work-piece table with T slot configuration

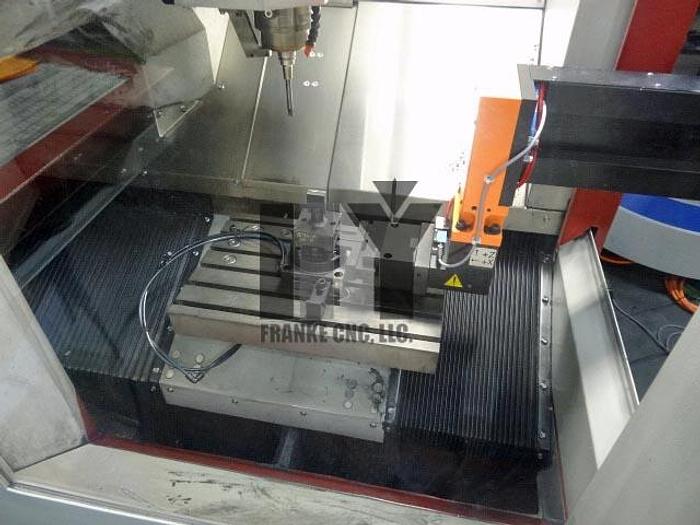

Spindle 3000 to 40,000 RPM, type MFW1024/40 HSK-E32

-Includes automatic tool change capability

-Maximum tool diameter 0.400in (10 mm)

-Includes greased bearings with automatic lubrication

-Fully integrated into machine control

-Equipped for HSK 32 tool interface

Laser tool length measuring device

-For automatic tool length, diameter, custom taper and contour measurement

with breakage and wear control

-Fully integrated into RMS6 CNC control

-Safely hidden in sealed tool changer compartment

Automatic tool cleaning station

-Compressed air-blast cleaning of cutting tool before laser measurement

-Tool moves to the cleaning station automatically when the CLEAN cycle is

programmed

Work piece cleaning

-Pressure air jet for cleaning of the work piece by air, integrated into

the Z-axis

Hand held pendant

-For manual operation of the axes during set-up, includes override control

RMSEdit

-Program editor for modifying and creating NC programs

comparison, tool for simple file modification, special search functions

-Ethernet network connection

-1GBit/sec; Interface for the integration of the machine control into an

Ethernet-network by the customer

Chip Removal

-Collecting bin below the machine bed

Automatic tool changer, RXP400

Rotary door for the tool changer

-Rotary door for the tool changer for manual tool change during production

time

3-D Touch Probe (Manual)

-Fixture with collet for probe and reference pin included

Automation package (RXP200-600)

-Includes automatic door for robot loading and un-loading

-Includes DIO card for connection to an external loading system

RMSMain/RXP

-Includes Roeders Job Manager (standard version) for the operation of a

single machine, with or without handling for tools and workpieces

RMS6-PH/Wp

-Includes software interface for connecting the Roeders machine control

Fanuc, and Zimmer+Kreim

a single gripper

High Accuracy Package

-Measurement of spindle growth with non-contact sensor

-Fully integrated into the machine control

Chuck drive single-2 pieces

-Includes pneumatic control of a single automatic chuck with clamping

check, chuck needs to be ordered through Roeders. When a handling system

is used, the chuck will be controlled by the handling system

-MACHINE DESCRIPTION-

Work Envelope

Table Dimensions

X....................................................... 17.1" (450 mm)

Y....................................................... 11.8" (300 mm)

Max. Workpiece Weight

220 lbs. (100 kg)

Axis Drive Motors

Linear Motors in all three axis, water cooled

Guideways

Deutsche Starr super precision linear guides with recirculating roller

bearings, standard cooling of bearings

Feedrates

0-1575 IPM (40M/min) on all 3 axes

Machine Weight

7,040 lbs. (3,200 kg)

Machine Dimensions (including control cabinet)

8' wide, 6.3' deep, 6.8' high

Max. Ambient Temperature Allowed

95 degrees F

Sealing

All machine components are protected against contamination. With an

industrial vacuum cleaner, graphite, cast iron and plastic can be

machined

Cabin

Fully enclosed, two doors with safety glass, good view into the working

area, simple work piece loading by crane is possible. For the automated

loading of the machine an automatic door is available on request

Cooling

Chiller for tempering of the spindle, drives and cabinet

-CONTROL DESCRIPTION-

PC based control uses two Pentium 3.2 GHz level computers

17" flat screen monitor

Control operates under Windows XP

Easy to learn, user friendly Windows interface

1 Gigabyte RAM (more RAM available on request)

250 Gigabyte hard drive (larger drives available on request)

Industry leading 10,000 block look ahead

CNC control automatically assign best acceleration/deceleration based on

cutter path geometry

Standard CNC can control up to 5 axes simultaneously

PLC interface allows for easy connection of accessories

Software axis limit switches

Built in "post" postprocessor allows Roeders control to run CAM files

configured for other machines control formats without requiring

"reposting" for Roeders format

User can control which G and M codes to disregard when running part files

file run, when it was run, total run time, error codes, etc.

Automatic 2D cutter radius compensation with collision detection

Automatic 3D cutter radius compensation (CAD file must give XYZ of tool

tip and tool vector)

Automatic sister tool function changes tools during operation (based in

cut distance)

Specifications

| Manufacturer | ROEDERS |

| Model | RXP 400 |

| Year | 2012 |

| Condition | Used |

| Stock Number | 064165 |

| Status | Available |

| Number of axis | 3-Axis |

| Tool changer | 18 ATC |

| Control | RMS6 CNC |

| Spindle | 40,000 rpm |

| Spindle taper | HSK-E32 |

| X axis | 16.1" (410 mm) |

| Y axis | 11.8" (300 mm) |

| Z axis | 8.3" (210 mm) |

| -includes the following features | Syntax highlighting, tool for file |

| -tool changer capacity | 18 positions, HSK 32. Includes collision detection |

| (rms6) to an external handling system from | Roeders, System 3R, Erowa, |

| -includes the following interfaces | Work piece changing is possible with |

| Machine history file stores ongoing machine history information | name of |

| Note | ROBOT SHOWN IN PHOTOS DOES NOT COME WITH THE MACHINE! |